Your location:Home >Automotive News >

Time:2022-06-15 12:33:04Source:

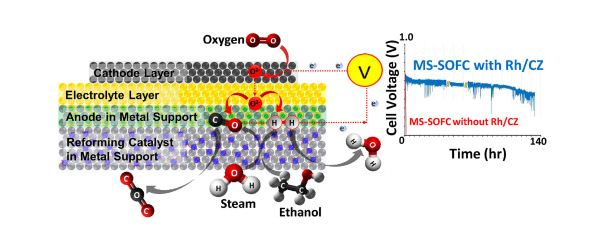

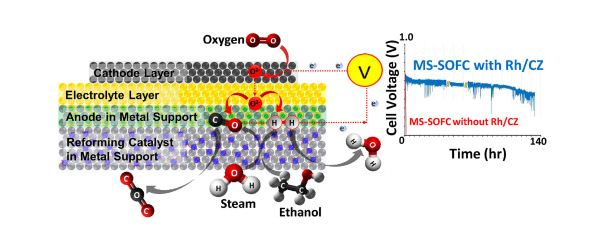

A team of Washington State University (WSU) and Nissan has integrated a catalyst layer into a metal-supported solid oxide fuel cell (MS-SOFC) for direct-to-ethanol operation,media reported.

(Image credit: sciencedirect)

The team introduced a rhodium-cerium-zirconia (Rh/CZ) internal reforming catalyst layer by infiltrating rhodium (Rh), ceria (CeO2) and zirconia (ZrO2) precursors into a stainless steel (SS 430) scaffold MS-SOFC.

At 600 °C, the ethanol solution (45 vol%) was directly fed into the anode.The experimental results show that the cells infiltrated with 5 wt% Rh/CZ exhibit better performance than cells without the catalytic layer due to the enhanced internal reforming activity of ethanol during syngas production.

The maximum current density is increased from 0.3 A cm−2 to 0.4 A cm−2, and the long-term stability is also significantly improved.Later battery analysis showed that the use of the infiltrated catalyst layer could prevent severe coke deposition in the functional layer of the negative electrode of the battery.

For futureelectric vehicles, this integrated reforming catalyst and MS-SOFC system is an efficient way to deliver bioethanol into SOFC technology, according to the researchers.

In 2016, Nissan announced it was developing a solid oxide fuel cell (SOFC) powertrain that uses bioethanol as an onboard hydrogen source.The company has numerous research collaborations in this area.

Statement: the article only represents the views of the original author and does not represent the position of this website; If there is infringement or violation, you can directly feed back to this website, and we will modify or delete it.

Preferredproduct

Picture and textrecommendation

2022-06-15 12:32:38

2022-06-15 12:32:01

2022-06-15 12:31:36

2022-06-15 12:31:09

2022-06-15 12:30:14

Hot spotsranking

Wonderfularticles

2022-06-15 12:29:33

2022-06-15 12:28:55

2022-06-15 12:26:10

Popularrecommendations