Your location:Home >Automotive News >

Time:2022-06-15 12:41:09Source:

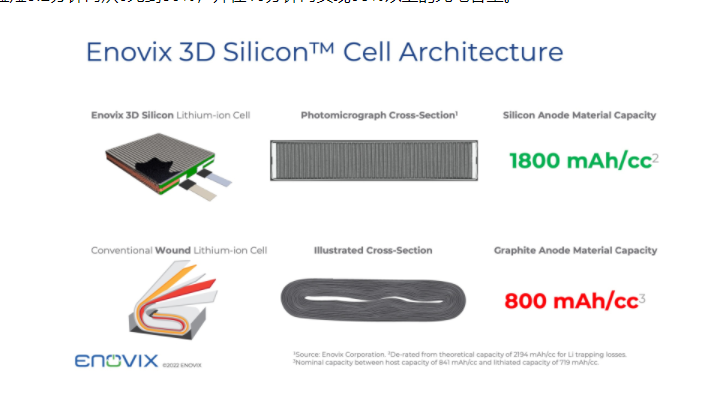

According to foreign media reports, BASF has expanded its Licity anode binder series for the manufacture of lithium-ion batteries.Licity 2698 XF, a second-generation styrene-butadiene rubber (SBR) binder, helps achieve more than 20% silicon in the anode, especially for SiOx and silicon-rich anodes.

(Image credit: BASF Corporation)

In addition to the stated properties of the series, the adhesive helps achieve higher capacities, increase the number of charge-discharge cycles, and reduce the number of recharges.

In addition, Licity 2698 XF is manufactured according to the biomass balance method.In this way, biomass is fed into the production process and distributed to binders.From the raw materials used in the production of Licity adhesives to the delivery of the product, BASF is committed to achieving economic goals while fulfilling social and environmental responsibility.

Licity adhesives are designed as waterborne carboxystyrene-butadiene copolymers with very low levels of volatile organic compounds (VOCs).This water-based binder has high colloidal stability an d is very compatible with co-binders such as CMC, and is designed to overcome the limitations of lithium-ion batteries.Licity adhesives have excellent processing properties, as well as excellent coating properties, in addition to excellent mechanical and electrochemical properties.

In addition to the new second-generation Licity 2698 XF series, BASF also introduced the Licity 2680, 2688, 2668 F and 2678 first-generation product grades.

Statement: the article only represents the views of the original author and does not represent the position of this website; If there is infringement or violation, you can directly feed back to this website, and we will modify or delete it.

Preferredproduct

Picture and textrecommendation

2022-06-15 12:40:45

2022-06-15 12:39:53

Hot spotsranking

Wonderfularticles

2022-06-15 12:35:41

2022-06-15 12:34:54

2022-06-15 12:34:29

Popularrecommendations